Stay up to date with everything that is happening in the wonderful world of AM via ourLinkedIncommunity.

Hexagon’s Manufacturing Intelligence divisionhas unveiled new capabilities in 3D printing with a technology that eliminates costly trial-and-error in precision metal part production. The innovative Advanced Compensation approach uses advanced geometry compensation to ensure large or complex metal parts distort into their intended shape during printing. Combining process simulation and 3D scan compensation, the most challenging parts with tight quality tolerances can be printed successfully with just one prototype build.

Despite its transformative potential, additive manufacturing has faced several barriers that have slowed the pace of adoption in safety-critical and precision-engineered applications such as machine building,aerospace, and medical prosthetics that require high surface quality, repeatability, and dimensional accuracy. The complex physical processes of laser powder bed fusion (LPBF) printing often lead to inconsistencies, deviations, and defects that are of unacceptable quality for complex parts with tight, critical tolerances.

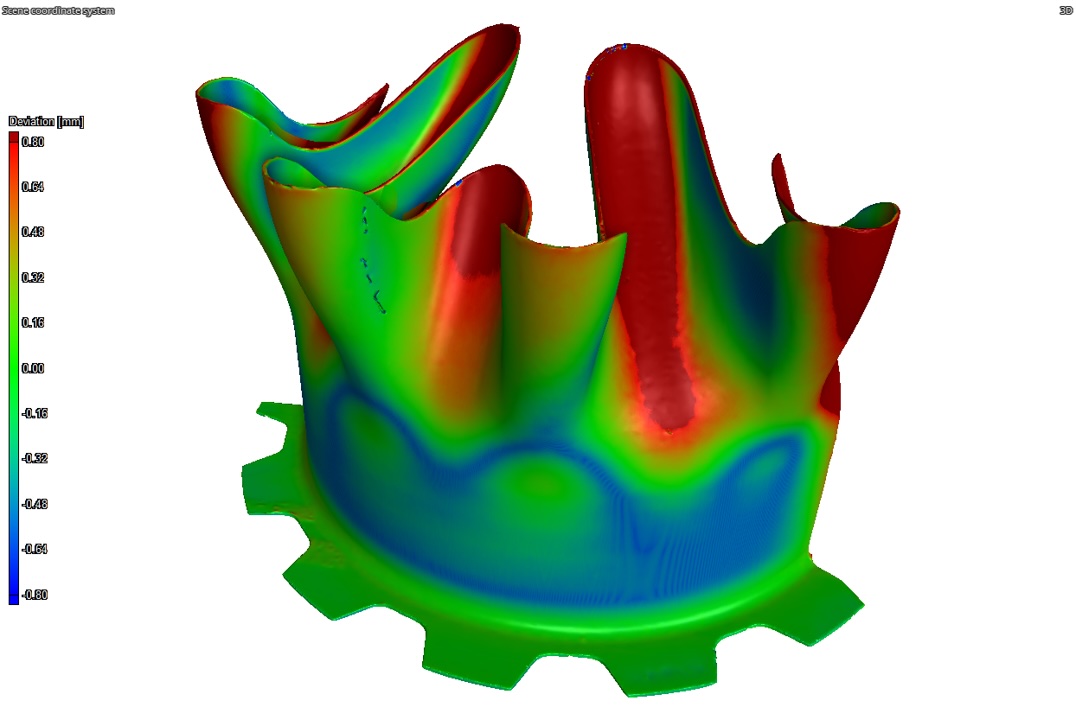

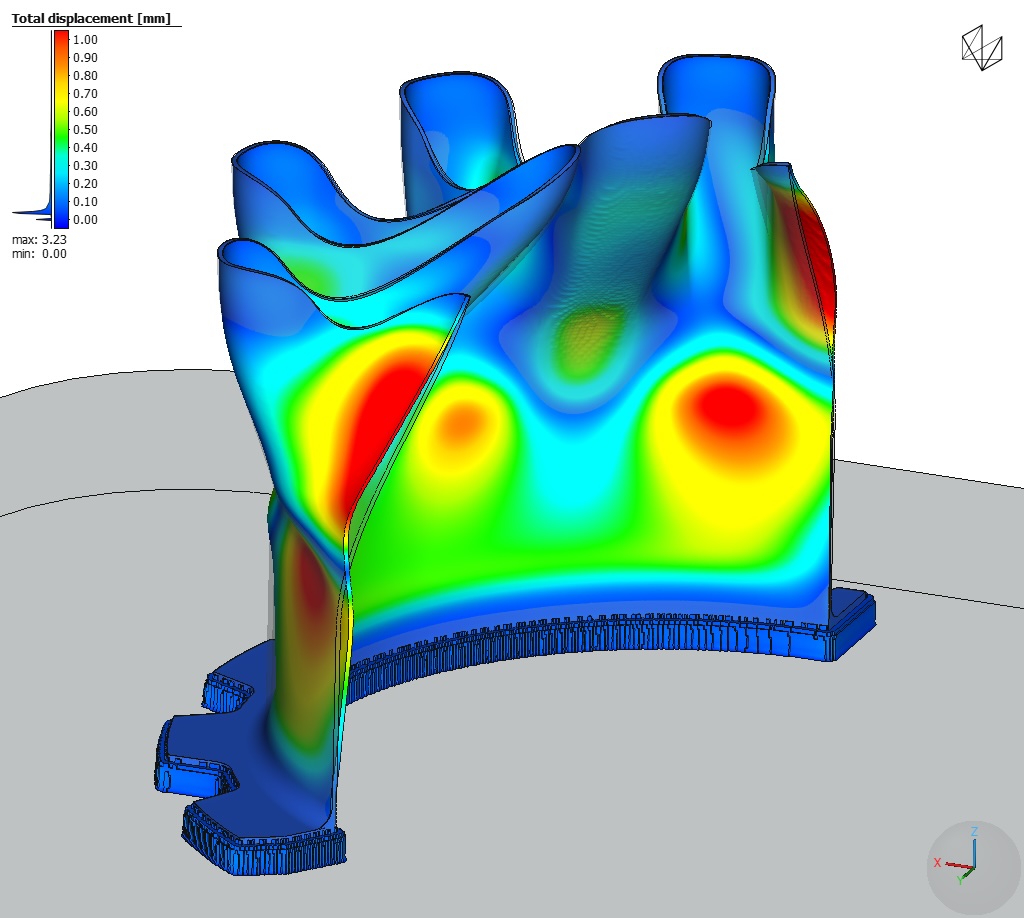

Hexagon’s Simufact Additive software is trusted by leading manufacturers to predict distortions and shrinkage with accurate simulations – helping eliminate print trials for most accuracies of parts with global compensation methods. For parts with more complex features, the company’s VGSTUDIO MAX software has become indispensable for AM because its powerful metrology and 3D scan analysis capabilities make it easy to compensate the printable mesh based on the measured deviations from an optical or CT scan and address localized distortions.

Hexagon’s most demanding customershave adopted a new approach called Advanced Compensation to achieve consistently high quality – even with thin walls that are prone to buckling, or challenging materials such as titanium or Inconel. This hybrid process combines process simulation with metrology-based compensation, fast-tracked high-quality prints – achieving surface profiles that are 98-100% within tolerance.

Additive Industries, a 3D printer OEM, was able to print a stainless-steel jet engine exhaust mixer with 0.2mm precision with just one prototype build. “Thanks to Advanced Compensation, we successfully printed a large 316L steel component with an impressive surface tolerance of +/-0.2mm – despite natural distortion of over 3mm in previous builds. Achieving this precision required only one previous trial build, reducing time [and] material waste, and allowed us to reduce the supports structure to the bare minimum. This level of control and efficiency opens up new possibilities for large-scale additive manufacturing applications,” said Alex Redwood, Head of Applications and Additive Studios at Additive Industries.

This workflow is now built intoHexagon’s Simufact Additive software. This integrated experience makes it accessible to any engineer using Simufact Additive, so they can pre-deform a part for global distortions using simulation and then compensate that same print-ready mesh using a 3D scan. No metrology experience is required because the metrology-based compensation utilizes powerful VGSTUDIO MAX technology that can accept imperfect or incomplete 3D scan data to create a clean mesh that morphed from the nominal CAD – removing a practical barrier to this important compensation method.

“If you’re making a large complex geometry, simulation will save you time and money – even for a one-off part. But when simulation alone isn’t enough, we’ve made it much easier to take an optical 3D scan then compensate those remaining problem features so you can print ‘second time right’,” said Mathieu Perennou, Director of Additive Strategy at Hexagon. “This data-driven approach takes the guesswork out of printing small batch parts, and it can be scaled up to refine a process for larger volumes using digital twin approaches that consider not just the geometry, but also the machine parameters or material behavior where part performance is critical.”

Material matters

As a partner to global manufacturers and their suppliers, Hexagon is uniquely able to improve the quality of AM from validating design concepts to enabling the certification of parts. Where a patient’s safety or an aircraft’s performance is at stake, understanding the material quality can be vital. Here, PBF Process & Defect Analysis (PDA) capabilities developed withRaytheon Technologiesenable additive teams to quickly predict the type and location of defects in LPBF parts within Simufact Additive. This insight helps teams optimize process parameters for quality and speed, and to reduce the cost and effort of certification by focusing destructive andnon-destructive testson problem areas.

As a productivity driver for advanced manufacturing, VGSTUDIO MAX is used to verify the quality of the powder feedstocks and to validate the internal structure of parts when printed. Its automated classification of features, high-productivity user experience, and powerful 3D visualization make it easy to perform root cause analyses, or quality assurance for verifying the quality of the complex structure and the printed metal’s properties from CT scan data as illustrated in an engineering breakthrough in custom medical implants recently achieved by Tel Aviv Medical Center, PTC, and Hexagon.

Advanced Scan Compensation will be available to all Simufact Additive customers in the Q1 2025 release.