Source: Pawel Slusarczyk archive

Stay up to date with everything that is happening in the wonderful world of AM via ourLinkedIncommunity.

It’s difficult to find a manufacturing company that doesn’t support ecology. Even if they don’t believe in it, aren’t interested in it, or their production methods contradict environmental protection principles — green always dominates in their official communication (unless it’s June — then there might be more colors for a moment).

3D printing is no exception. When ecology became a dominant theme in marketing, it was immediately claimed that AM is the most ecological manufacturing technology of all. Generally, this is largely true (although there are some notorious exceptions, which I will cover in a separate article), so running a business in this field should not only be easier but also extra rewarding.

Right?

Well, I’ll tell you how it is. I’ll tell it from the perspective of a person who has been running a company specializing in eco-friendly 3D printing for three years.

Wrong.

When it comes to placing an order — no one really cares…

Ecology is a slogan

Source: Pawel Slusarczyk archive

My company —GREENFILL3D— specializes in producing applications from ecological materials — specifically biodegradable or compostable bioplastics. When it comes to producing things — parts, components, prefabricates, or final products, the following factors are primarily considered (order is random):

durability (mechanical, thermal, chemical, etc.)quality (finish/surface and dimensional accuracy/conformity to design)weightproduction and delivery timeprice.

Sometimes color and material origin are also considered. And this is the only place where the phrase “ecology” appears.

So, the ecological aspect is taken into account:

either not at allor at the very endor as an additional option.

From my experience, even if a customer starts the conversation with bioplastics or recyclates (i.e., an application has an ecological requirement), when it turns out that they negatively impact any of the conditions from the first list, they are ready either to switch to “forever plastic” or to give up on additive manufacturing altogether (and consequently choose, for example, production from wood or cardboard, which are still perceived as perfectly ecological alternatives).

But let’s start from the beginning…

Ecology of plastics

Source: Pawel Slusarczyk archive

In the context of ecology, in the area of plastics we can make the following division:

plastics derived from fossil fuelsplastics that are recycledbioplastics.

The first group dominates and includes the vast majority of plastics in the world. Their production uses residues from fuel production (oil) and other chemical compounds, which together determine their unique physicochemical properties.

They have a number of advantages — they are cheap and quick to produce, they are durable, lightweight, etc., and one key disadvantage — after a period of use they remain with us forever… In the past — in the 60s, 70s and 80s, this was not such a big problem. It was enough to collect them and put them in landfills. But in the 90s it turned out that there was so much plastic that there was not enough space in landfills.

They started to process it — to recycle it, but it turned out that this process is problematic and inefficient. It is much easier to produce new plastic than to recycle it.

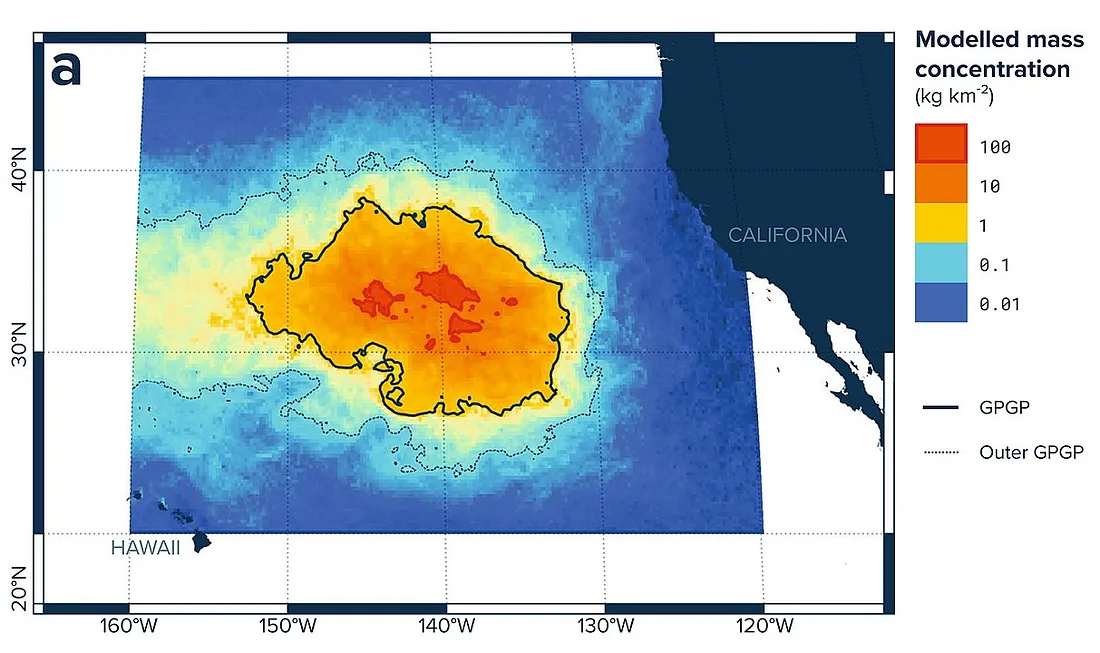

When it is burned, it gives off toxic fumes and it is even worse. When it is buried, it does not solve the problem of lack of space; besides, digging holes in the ground is expensive. The solution turned out to be throwing plastic waste into the oceans. After all, the oceans occupy a much larger surface area of the planet than the land! Unfortunately, after 2020, this also became insufficient…

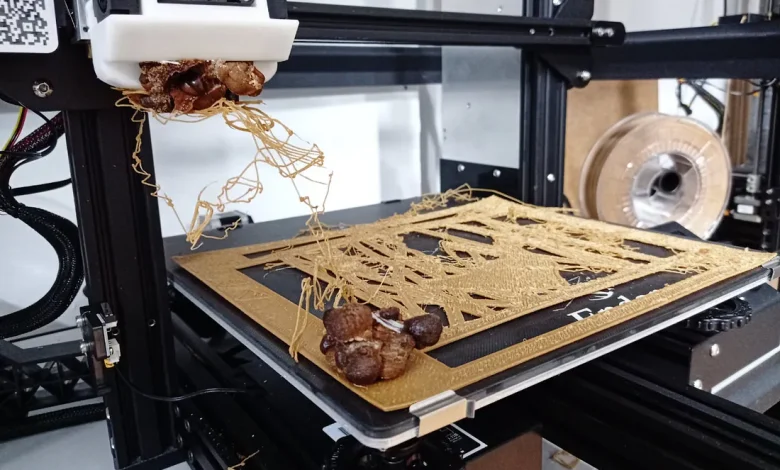

Plastic waste began to form islands!

By L. Lebreton, B. Slat, F. Ferrari, B. Sainte-Rose, J. Aitken, R. Marthouse, S. Hajbane, S. Cunsolo, A. Schwarz, A. Levivier, K. Noble, P. Debeljak, H. Maral, R. Schoeneich-Argent, R. Brambini, and J. Reisser — https://www.ncbi.nlm.nih.gov/pmc/articles/PMC5864935/pdf/41598_2018_Article_22939.pdf, CC BY 4.0, https://commons.wikimedia.org/w/index.php?curid=107377724

Additionally, sea currents began to degrade the plastic, transforming it into microplastics. This was either ingested by marine organisms and ended up on land as food, or the sea breezes carried it to the beaches. Either way, it turned out that plastic returns to humans — but not as a product, but as a poison that kills!

The topic was taken up by bright minds from all over the world — scientists, politicians, mainstream media journalists, artists, athletes and all the rest of the celebrities. The matter began to become serious (i.e. it was from the beginning, but now it was official).

Plastic began to be perceived as a deadly threat.

It turned out spontaneously and naturally that ecology is a great marketing medium. That when you use ecological products, you are more sensitive to problems, more enlightened and better. Ecology makes people better. So ecology began to become fashionable.

Alternatives to forever plastics

Source: Pawel Slusarczyk archive

As I mentioned above, the alternatives to forever plastics are recyclates and bioplastics. In reality, recyclates would be the best solution if not for the still complicated process of their production. Or to put it differently — processing plastics is not difficult in itself, what is complicated is their segregation and differentiation. Each plastic has different properties, which is due to a different chemical composition. Some plastics are very similar to each other — others are different in everything.

If we mix several types of plastics in uncontrolled, random proportions — then “something will come out of it”. Unfortunately, if we care about a good quality product, such a mixture is useless. What’s more, in some technological processes it cannot even be used (the material must be clean).

Until highly efficient methods of segregating plastic waste are developed, recycling will be only an “additional option”. In all this, bioplastics look much better — materials of organic origin that decompose in the process of biodegradation or composting.

What are bioplastics?

Source: Pawel Slusarczyk archive

Bioplastics are polymers that are created as a result of the chemical synthesis of some natural raw material. The most popular bioplastic in the world is polylactide (PLA), which comes from cornstarch or sugar cane. Polylactide has been used for many years in the food and medical industries to produce various types of packaging or disposable dishes, plates, cutlery, and drinking straws.

When the RepRap project — the first amateur FDM/FFF 3D printer for self-assembly — was being developed, the idea arose to use PLA instead of the then-popular ABS. ABS has much better physical properties compared to PLA, but it is more difficult to use in 3D printing due to the shrinkage that occurs during the cooling of the material layers. In the case of PLA, the shrinkage is minimal — and additionally, it does not emit an unpleasant smell during melting. Thus, PLA won the hearts of 3D printer users and became the dominant material around the world.

But bioplastics are not only polylactide. There is potato starch. There is cellulose. Additionally, each of these bioplastics can be mixed with other raw ingredients such as wood dust, algae, flax, hemp, coffee grounds, or wheat bran from pasta production…

Biodegradability and compostability

Source: Pawel Slusarczyk archive

A biodegradable plastic is a material that decomposes under the influence of microorganisms such as bacteria, fungi, or molds into smaller components such as carbon dioxide, water, and biomass. This process involves the natural decomposition of the material, which allows for a reduction in the amount of waste introduced into the environment and a reduction in the consumption of natural resources.

Biodegradability and compostability are two different processes that are often confused with each other.

Composting is the process of biological decomposition of organic substances by microorganisms in the presence of oxygen, leading to the formation of humus — a substance rich in nutrients.

Source: Pawel Slusarczyk archive

Biodegradability, on the other hand, is not related to the presence of oxygen and can occur in various conditions, both aerobic and anaerobic. Unfortunately, PLA cannot biodegrade in natural conditions. It can only occur in specific, controlled conditions, such as specialist composting plants. These conditions may include high temperature, appropriate humidity, access to oxygen, and appropriate pH. Potato starch, on the other hand, can be composted at home! It also dissolves in water.

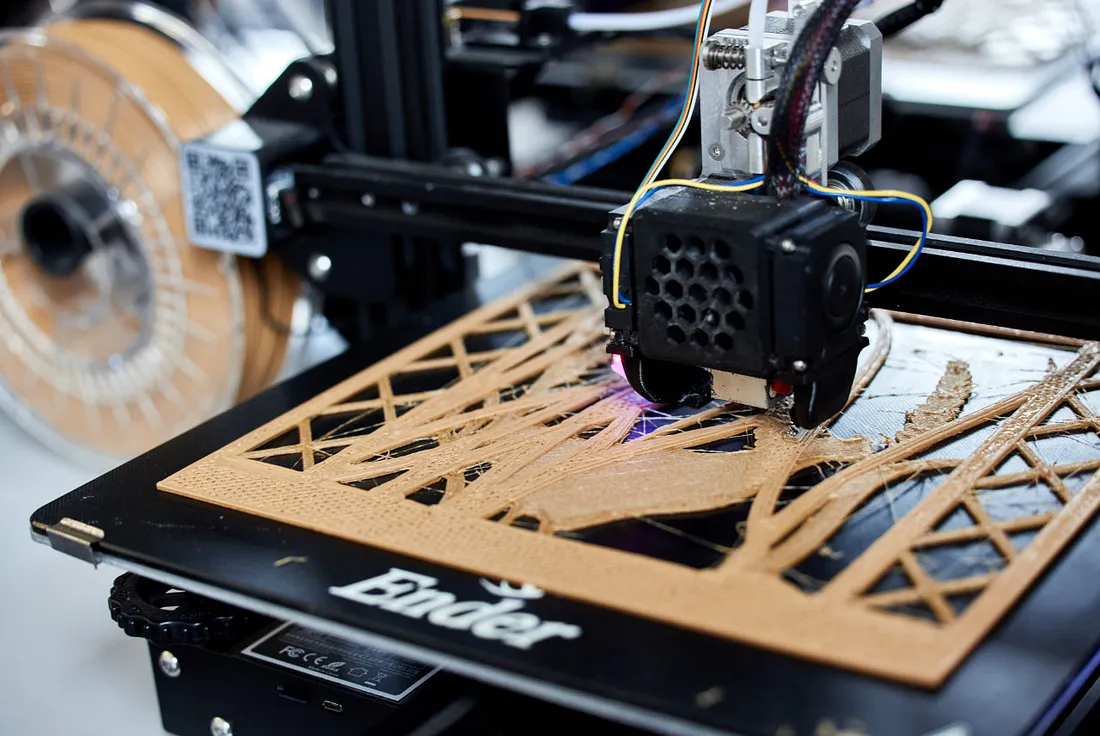

Additive manufacturing of bioplastic parts and products

Source: Pawel Slusarczyk archive

So…

We live in a world polluted with bad, toxic plastic. It lingers on land, in oceans, and has recently even been found floating in the air.We have a society aware of these threats, supporting ecological alternatives.We have materials that provide a solution to the problem — plant-based bioplastics that can biodegrade or be composted, disappearing forever.We have 3D printing technology, which is the most ecological manufacturing process and works perfectly with bioplastics.

Do we have a ready recipe for business success?

No!

We return to the initial list of factors considered when starting production (parts-components-products). Ecology is at the very end.

But why???

Because for the buyer, functionality and quality are always the most important, and ecology is a slogan — something they are ready to give up. I’m sorry, but that’s how it is. I write this based on over a hundred conversations with clients from different parts of the world (mostly from Western Europe).

Drawbacks of bioplastics

Source: Pawel Slusarczyk archive

In reality, aside from biodegradability/compostability and ease of 3D printing, bioplastics have no advantages…

They are not very durable.They are brittle/breakable.They have low thermal resistance (~60°C / ~140°F).Some are very susceptible to moisture, which activates the composting process.Due to the relatively low production volume compared to other plastics, they are usually more expensive than standard materials.

Here’s a typical conversation with a client about a part/product made of bioplastic:

– But is it cheaper?– No, it’s more expensive*.– So is it better?– No, it’s worse.– So what’s the point using it?– Because it’s ecological! Biodegradable or compostable!– Ekhm… I think I’ll get back to you… after some… I don’t know… further consideration…

*This conversation does not concern PLA, which is one of the cheapest plastics on the market. Unfortunately, every other bioplastic is more expensive.

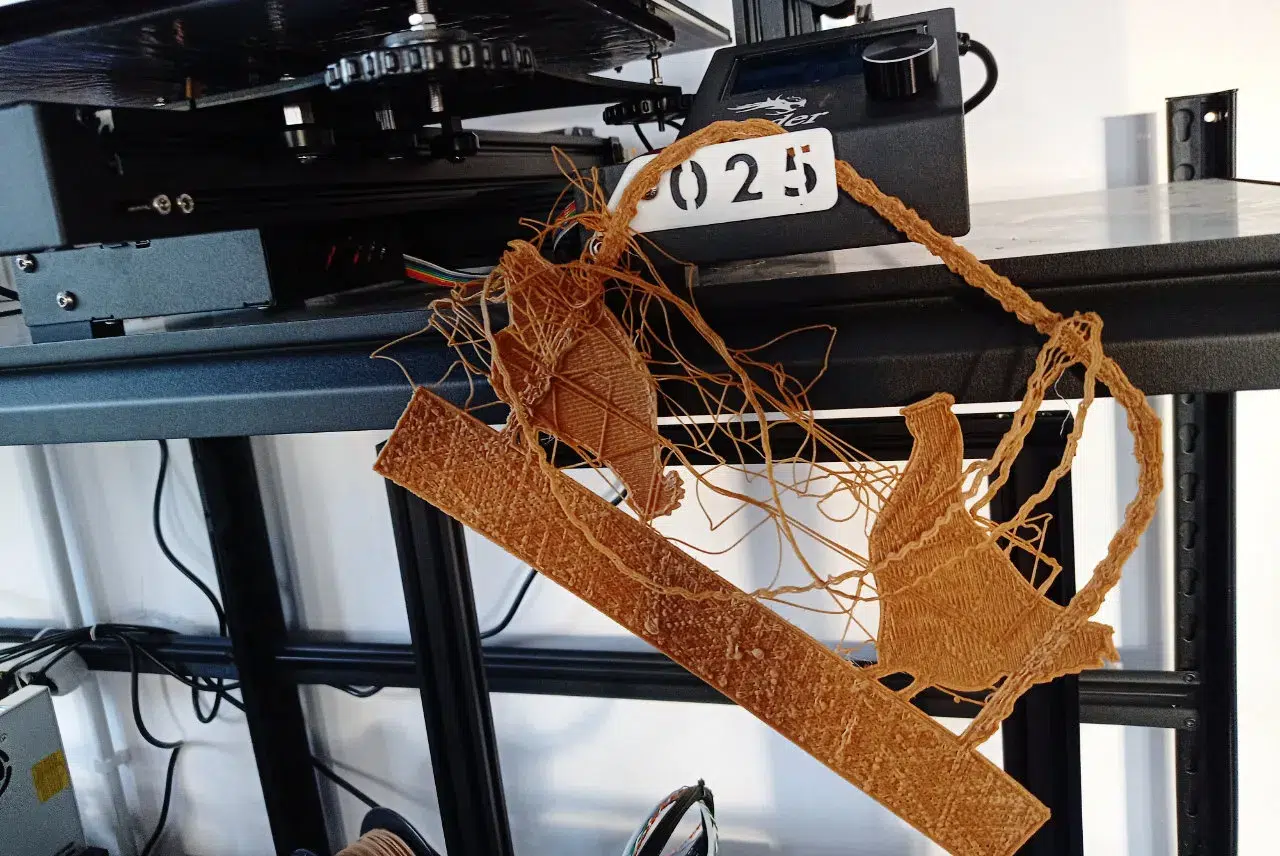

Where do bioplastics make sense?

Source: Pawel Slusarczyk archive

The biggest beneficiary of bioplastics is the packaging industry. That is, the production of all kinds of products that have a very short lifespan and immediately end up in the trash after use. Here, biodegradable or compostable materials make a real difference.

Unfortunately, 3D printing is only minimally suitable for this due to production scale limitations.

Another area of application is advertising, where 3D printing technology and materials used are part of the entire advertising campaign. Bioplastics are also suitable for education, where students print objects designed during classes on 3D printers. These usually have low utility and aesthetic value and quickly end up in the trash. Using bioplastics here also makes sense. There are, of course, many more ideas and applications (such as urns, lampshades, or home decor products).

Conclusion

3D printing with eco-friendly materials — though theoretically very intriguing and business-promising, is in reality a very difficult and demanding endeavor. Contrary to what it might seem, clients and consumers make purchasing decisions based on very realistic and practical motives.

The idea of ecology is still something rather abstract in the current 3D printing context.